Within the "Engineering Change Request", you will specify the details of the changes you would like to make within the Lines section of the change request.

Depending on the Source Type, the system will automatically populate the details of the existing manufacturing setup for you, with the only exception to this being if the "Engineering Change Request" was created from an Item (or Stockkeeping Unit) against which there is no existing Production BOM No., Routing No. or Production By-Product Code specified to the source record.

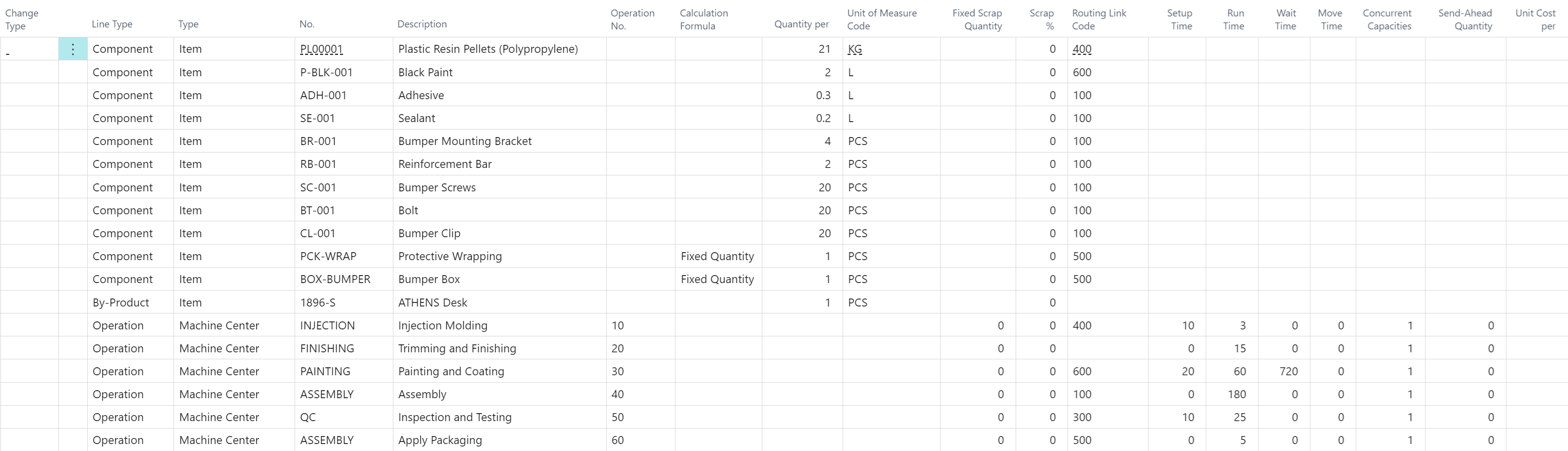

Information held within the Lines section of the "Engineering Change Request" screen is a combination of the information from either the Production BOM, Routing or Production By-Product and will enable the user to view the existing manufacturing details, with the following key information being shown for each Line regardless of the Source Type.

| Line Type | This attribute identifies whether the Line information relates to a Component, a By-Product or an Operation |

| Change Type |

The Change Type will be blank when Lines are created, but will be automatically updated based on the changes you are making, as follows:

|

| Type |

The Type, No. and Description are related to one another, with the Type being one of the following options.

|

| No. | Identifies the record that the Line is referencing, such as an Item No. or Machine Center No. |

| Description | This is the Description/Name of the specified record - as identified by the Type and No. |

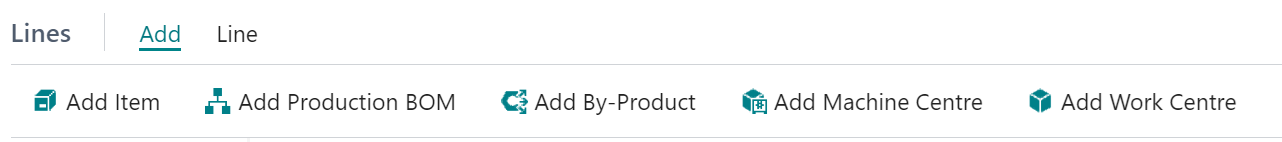

Add Menu

To propose the addition of Components (for BOMs), Operations (for Routings) or By-Products for an Item, you can use the features available from the Add menu of the Lines FastTab, as shown below.

-

Add Item - this will show the Item list from which you can add an Item as a Component

-

Add Production BOM - select a Production BOM which will be added to the "Engineering Change Request"

-

Add By-Product - will show the Item list from which you can then add an Item as a potential By-Product

-

Add Machine Center - shows the Machine Center list which will add the Machine Center as an Operation

-

Add Work Center - shows the Work Center list which will add the Work Center as an Operation

| Note: Within the main menu of the "Engineering Change Request" screen, there is also an option for Import, which can be used to import a Parts list from an external CAD solution. This will create Items in the say way that the above Add Item menu option works. |

Line Menu

The Line menu is used to adjust or add information to the selected Component/Operation/By-Product Line, with menu options being enabled based on the selected Line record.

-

Adjust - when this is used the current line is marked as Adjust (Old Values) and a new line is inserted and marked as Adjust (New Values)

-

Remove - this will mark the current line as Removed - stating that the Item/Operation/By-Product is no longer required

-

Explode Production BOM - is relevant if the selected line is a Production BOM and will replace the line with Component Lines of the Production BOM

-

Set Routing Link - can be used to associate a Routing Link Code to the selected line

-

Undo Change - will undo the change you have made

-

Comments - allows you add/view comments against the selected line

-

Where-Used - for lines that are Components, this will show you the Production BOMs against which the Component is used

-

Item Availability by - shows the availability of the selected line, for Components and By-Products, as available from the standard Business Central Item list

-

Select Item Substitution - shows the list of substitutes that are available for Components and once selected the substitute Item will be added to change request

It is only possible to update the Attributes for lines that have a Change Type of Adjust (New Values) or New and the Attributes that are editable is dependant on the Line Type, as only certain Attributes will be relevant, as detailed below.

| Operation No. | Calculation Formula | Quantity per | Unit of Measure Code | Fixed Scrap Quantity | Scrap % | Routing Link Code | Setup Time | Run Time | Wait Time | Move Time | Concurrent Capacities | Send-Ahead Quantity | |

| Component | X | X | X | X | X | ||||||||

| Operation | X | X | X | X | X | X | X | X | X | X | |||

| By-Product | X | X | X |

Options for Production BOM Changes

If you are making changes relating to Components, the "Engineering Change Request" screen has the following functions available from the Bill of Materials menu, which can help support you in the process of proposing changes or reviewing changes if you are responsible for approving a change request.

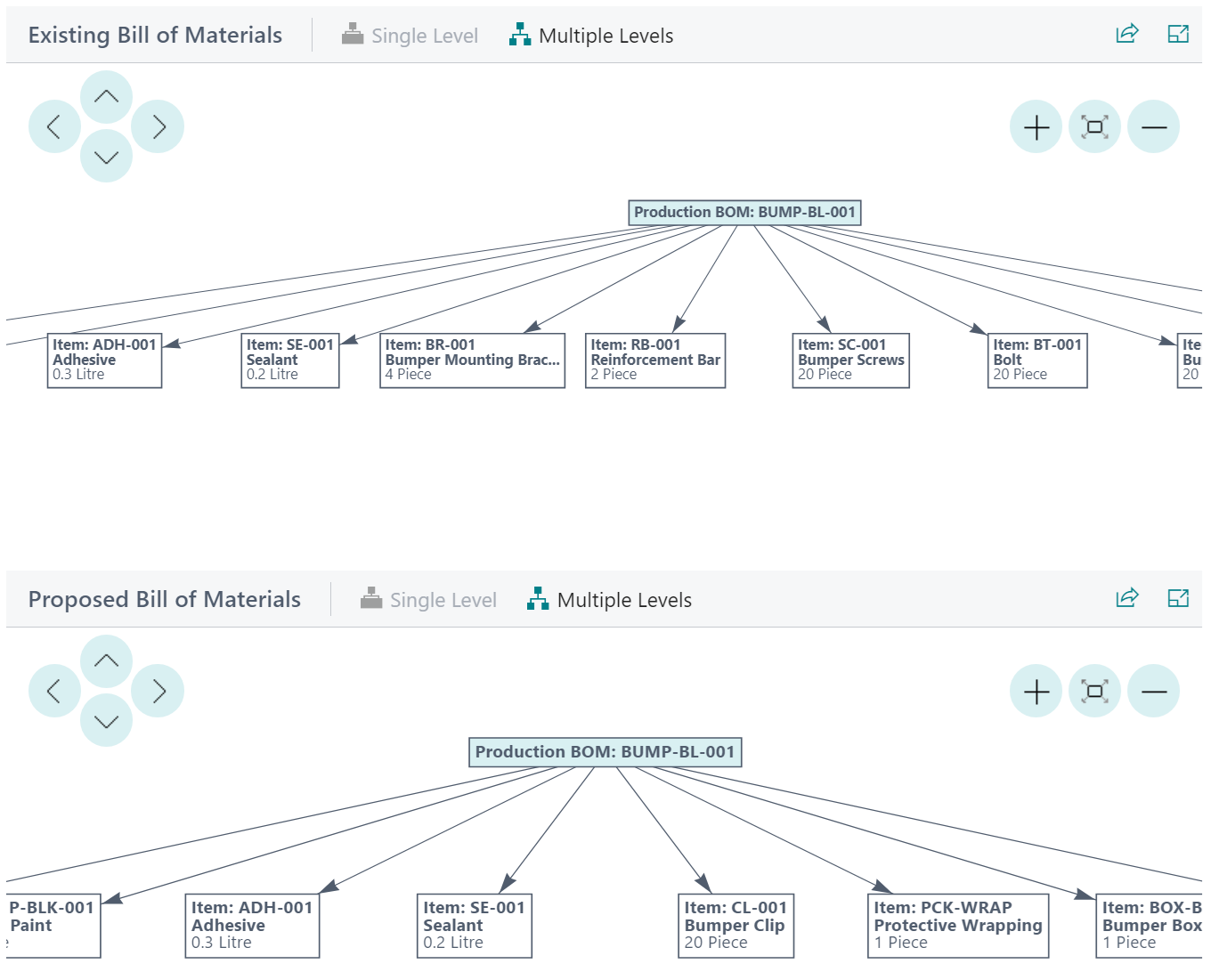

| Bill of Materials Diagram |

This let's you view the Bill of Materials in visual form, comparing the current and proposed BOM structure side-by-side

|

| Analysis |

This option enables you to see view statistical information relating to the usage of the current Production BOM, such as differences between expected and actual material usage alongside deviation data, often providing an insight or potential justification to support the proposed changes

|

Options for Routing Changes

When proposing changes that relate to Operations and therefore the Routing itself, the "Engineering Change Request" screen has the following functions available from the Routing menu.

| Check and Calculate Routing |

Will verify that the proposed Routing is valid in terms of sequence and structure, mimicking the same verification process that occurs when the Status of a Routing is changed to Certified |

| Routing Diagram |

Allows you to see the impact of the proposed changes to the manufacturing process in visual form, comparing changes against the current Routing

|

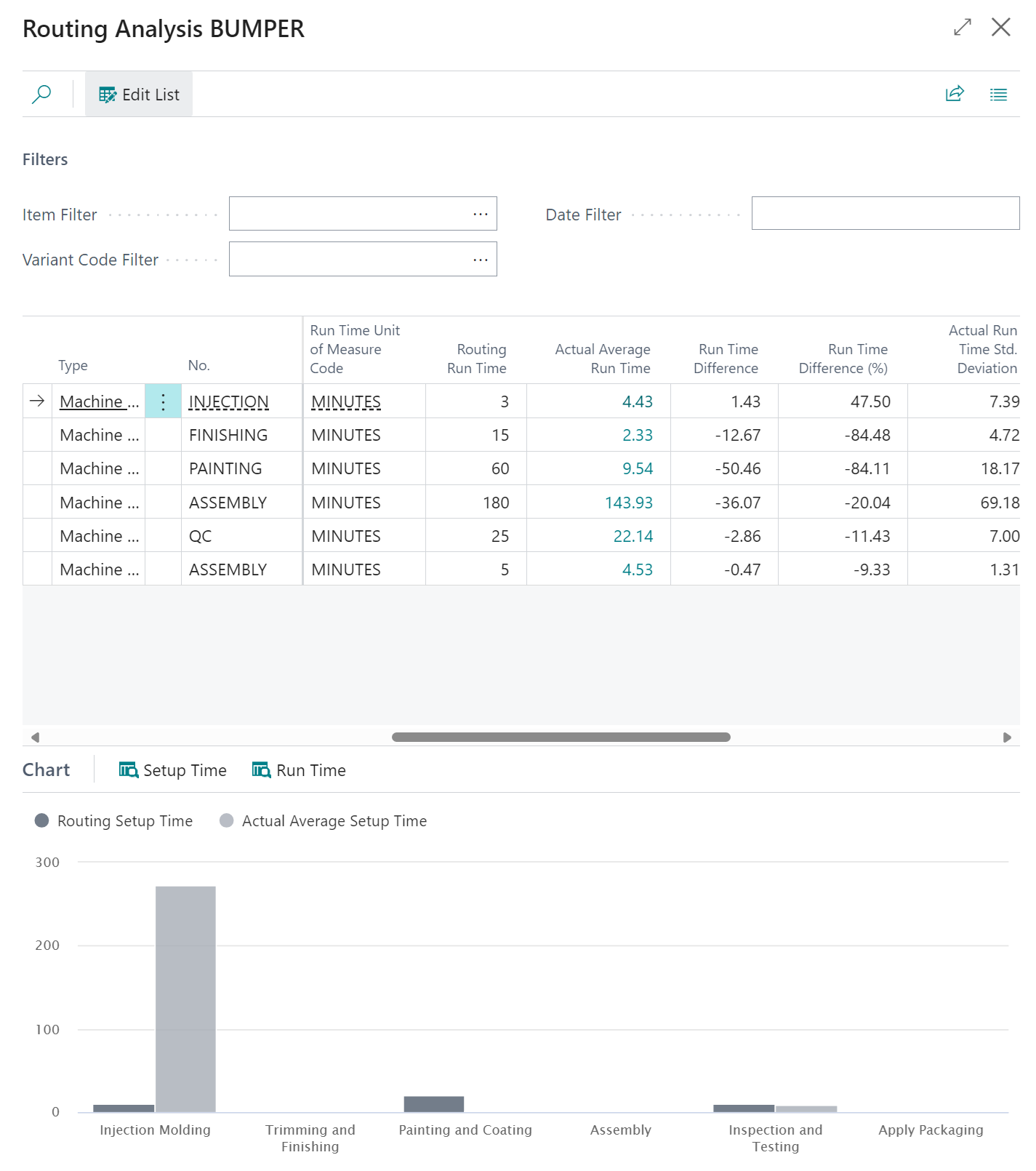

| Analysis |

Similar to the Production BOM Analysis screen, the Routing Analysis will show you statistical information relating to the usage information that has been captured from Production Orders

|

Options for By-Product Changes

For changes that are related to the modification of By-Product information within the system, the "Engineering Change Request" screen has the following feature, available from the By-Products menu.

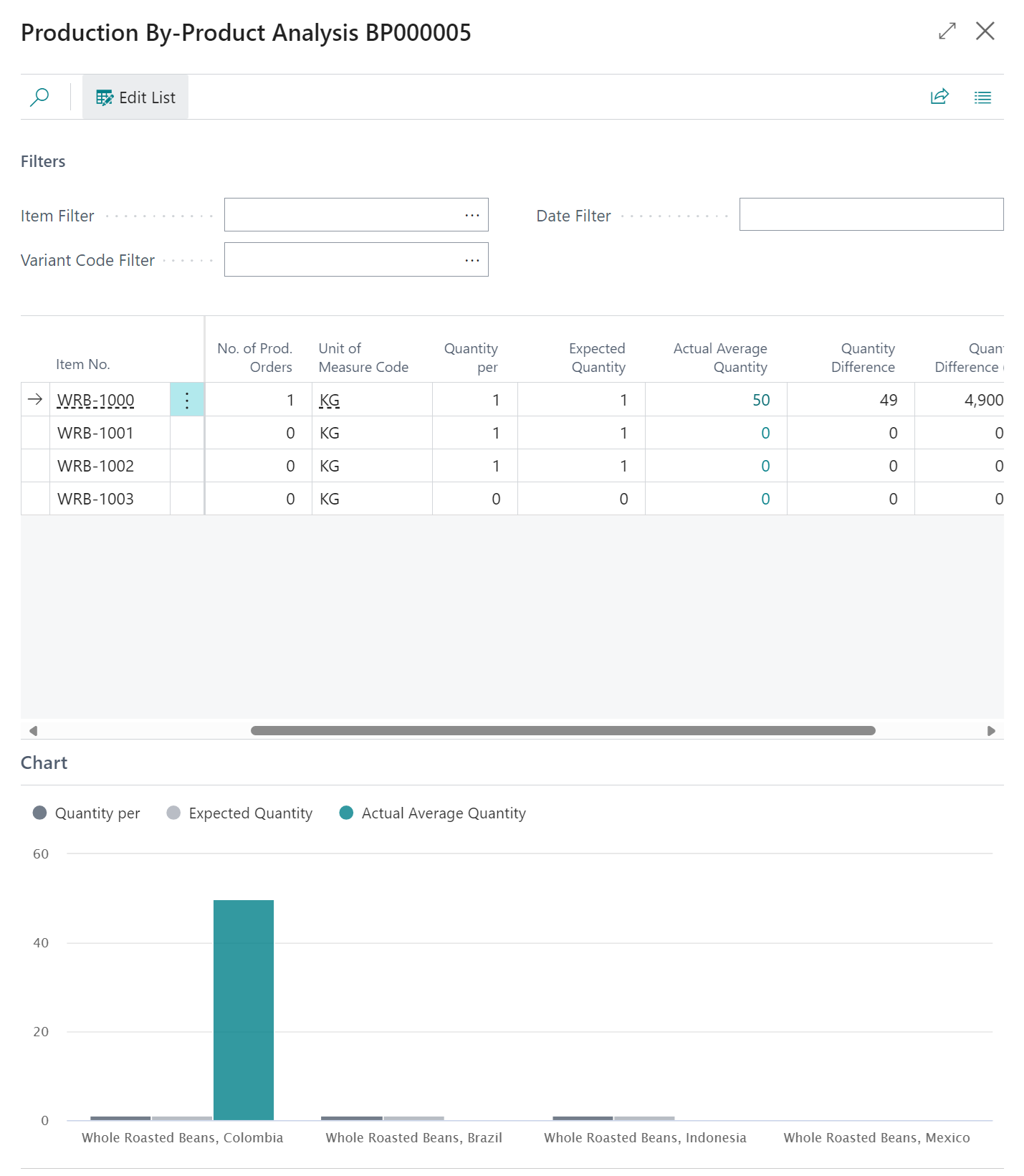

| Analysis |

Will identify the statistical information relating to the usage of current By-Products that are included within the Change Request.

|