Manufacturing Plus Tooling functionality provides a way to track the usage of a Tool in relation to the manufacturing process for which it is used.

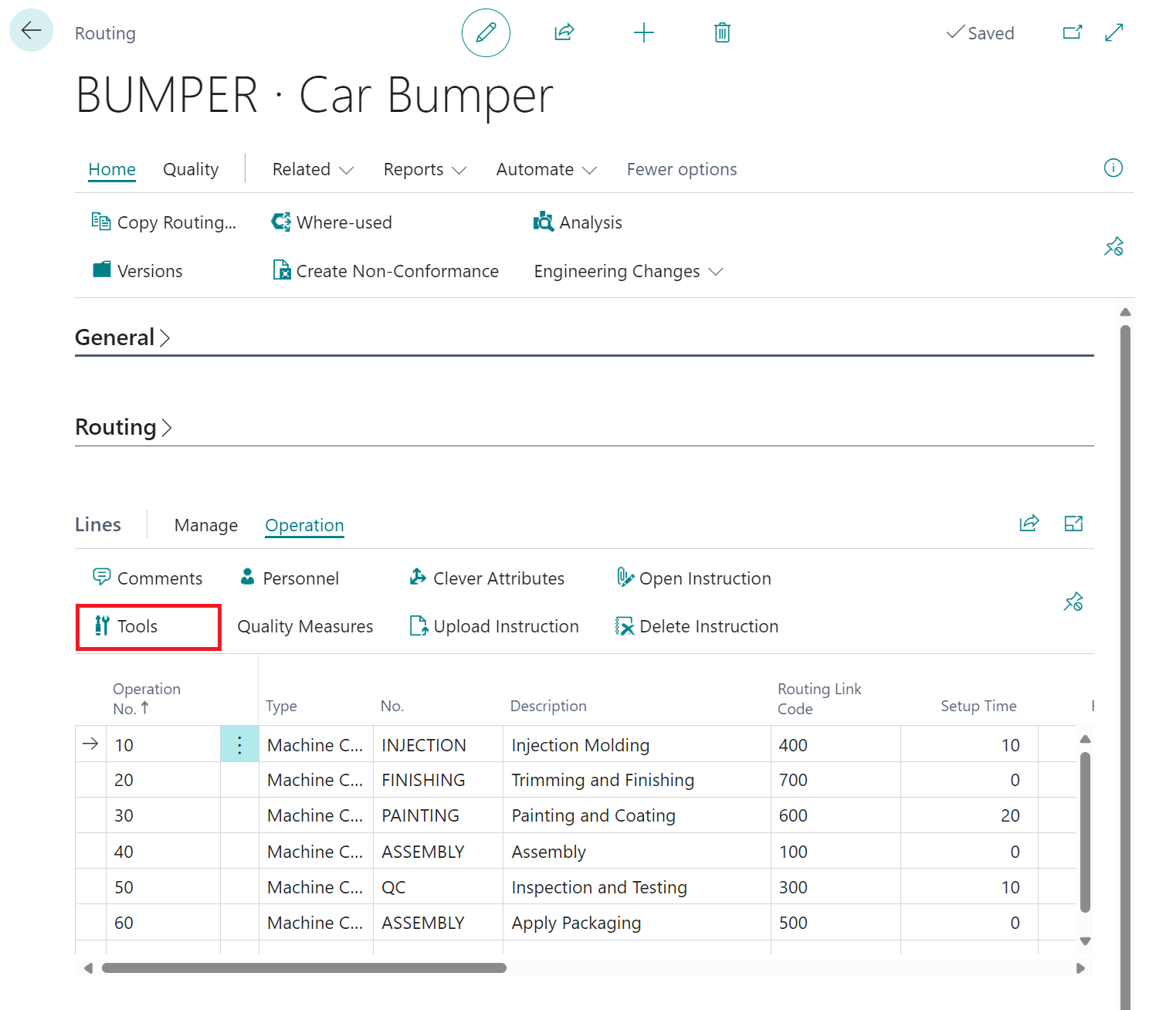

To identify the processes that a Tool is used for and to define details of how usage should be tracked in Business Central, we need to create the link between a Tool and the process using the Routing functionality and this is done from the "Routing" screen.

Within the Lines section of the Routing (shown above) you simply press the Tools option and this will open the Manufacturing Plus Tools List, which opens up the "Routing Tools" screen, allowing you to setup the Tool(s) that are required for the Routing Operation and also details about the Usage quantities to be registered against the Tool when the Tool is in use.

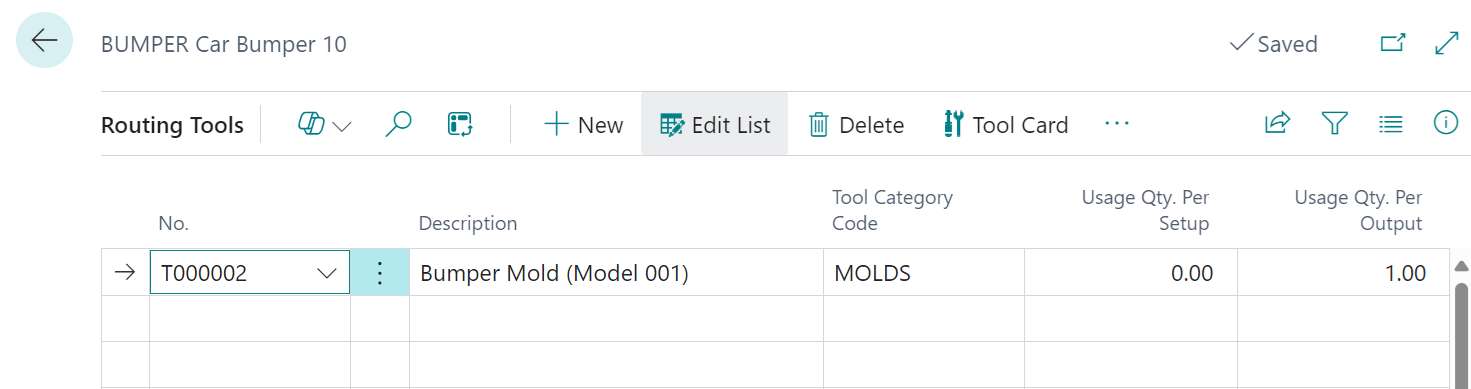

For each Tool that you wish to setup, the following information is required to ensure that the system correctly tracks the usage of the Tool when issued to a Production Order.

| No. |

Using the lookup, you can select the Tool that you wish to use when completing the manufacturing process. This will then automatically populate the Description and Tool Category Code the information held on the "Tool Card" |

| Usage Qty. Per Setup | This attribute will control how much usage is recorded against the Tool when the Setup process for the Routing Operation is posted in Business Central |

| Usage Qty. Per Output |

This attribute will control how much usage is recorded against the Tool for Output registered inside of Business Central. Usage will be posted based on a calculated value of the Output Quantity x Usage Qty. Per Output |