Intro

This document is for developers who wish to extend the functionality of the Clever MES app from Clever Dynamics.

Page Customisation

Most of the logic for defining the pages that are displayed in the web portal by MES is contained in the MES – Page Definition Mgt.” codeunit.

This codeunit builds populates data in the following temporary tables:

- Portal Framework Control - each record defines a control (button, grid, textbox, image etc.) that should be displayed on the page.

- Portal Framework Control Data – data that is associated with a control e.g. the data to be shown in cells of a grid control.

- Portal Framework Control Metadata – the metadata associated with a control, e.g. its type, colour, caption

The standard MES logic will populate these tables with records to define each page in the portal. The following integration events provided opportunity to override the standard logic.

- OnBeforeBuildPage – called before any of the standard logic is applied

- OnAfterBuildPage – called after the standard logic has been applied

- OnAddControlToPage – called immediately before each control is ‘added’ to the page i.e. before each record is included in the set.

These events can be used to manipulate the data contained in these temporary tables, which in turn will reflect the controls that are built by the portal.

OnBeforeBuildPage

This event is called before any of the standard logic for defining the page is called. The following parameters are included:

- ActivityCode – a code that denotes the type of activity for which a page needs building e.g. DataSelection, OutputScreen, ComponentSubform – see the xyzCode functions in the “MES – Activity Mgt.” codeunit.

- PortalFwkApplicationDevice2 – a record denoting the current Portal Framework Application device.

- DataTypeCode – when the requested activity is - DataSelection, this code indicates the type of data that should be presented to the user for selection.

- PortalFrameworkControl – the temporary table representing the set of controls

- PortalFrameworkControlData – the temporary table containing data associated with the controls

- PortalFwkControlMetadata – the temporary table containing metadata associated with the controls.

- ActivityLogEntryNo – the entry no. of the log record associated with this activity.

- Handled – a Boolean indicating whether the event has been handled (true indicates that the standard logic should not be called).

OnAfterBuildPage

This event is called after the standard MES logic has been applied. The same parameters are included as for OnBeforeBuildPage, except for the Handled parameter:

- ActivityCode – a code that denotes the type of activity for which a page needs building e.g. DataSelection, OutputScreen, ComponentSubform – see the xyzCode functions in the “MES – Activity Mgt.” codeunit.

- PortalFwkApplicationDevice2 – a record denoting the current Portal Framework Application device.

- DataTypeCode – when the requested activity is DataSelection, this code indicates the type of data that should be presented to the user for selection.

- PortalFrameworkControl – the temporary table representing the set of controls

- PortalFrameworkControlData – the temporary table containing data associated with the controls

- PortalFwkControlMetadata – the temporary table containing metadata associated with the controls.

- ActivityLogEntryNo – the entry no. of the log record associated with this activity.

OnAddControlToPage

This event is called for each control that is included in the temporary tables that is set by the standard logic. This gives the opportunity for the data associated with the control to be manipulated, the control “skipped” i.e. not included on the page and new controls to be injected before the current control.

The following parameters are included:

- ActivityCode – a code that denotes the type of activity for which a page needs building e.g. DataSelection, OutputScreen, ComponentSubform – see the xyzCode functions in the “MES – Activity Mgt.” codeunit.

- PortalFwkApplicationDevice2 – a record denoting the current Portal Framework Application device.

- PortalFrameworkControl – the temporary table representing the set of controls

- PortalFrameworkControlData – the temporary table containing data associated with the controls

- PortalFwkControlMetadata – the temporary table containing metadata associated with the controls.

- SkipControl – a Boolean indicating whether the control should be skipped. If this is set to true the current control will not be included on the page that is built by the portal.

Adding Controls

New controls can be added though use of the functions on the PortalFrameworkControl parameter passed by the above integration events.

The following functions can be used to create new controls:

- AddNewEntry – creates a new control below the current one and moves the pointer to the new control.

- AddNewEntryBefore – creates a new control before the current one and moves the pointer to the new control.

These functions require a ControlID. This should be a unique code that is associated with the control. This ID will be used in subsequent web service calls to NAV when activity occurs that is associated with this control. See Handling Device Activity.

Metadata

Having creating the control, metadata must be added to determine its type and appearance. Metadata records are added with the AddMetadata function. The following parameters are required:

- PortalFwkControlMetadata – a Portal Framework Control Metadata record. This will be populated with the appropriate values defined by the other parameters and inserted.

- Name – the name of the metadata. See Metadata Names and Values for a list of valid metadata names and values.

- Type – the type of the metadata. This is an option: 0 = Element, 1 = Attribute. The correct value for this parameter will be determined by the metadata name.

- Value – the value of the metadata. See Metadata Names and Values for a list of valid metadata names and values.

If you use these functions to create a new control you will need to implement an event subscriber to handle the activity associated with the control. For example, if you add a new button control you need to provide a handler function for to determine the correct response to that button being clicked.

Metadata Names and Values

Below is a list of the valid metadata names and their corresponding values.

| Name | Type | Value |

|---|---|---|

| type | 0 | button, text, selectiontiles, selectionlist, image |

| caption | 0 | The text of the caption |

| value | 0 | The value to display in the control |

| colour | 1 | Any value that is valid for HTML i.e. hex value, name of colour |

| placement | 1 | 'right'/'left' |

| subform | 1 | true/false |

| layout | 1 | 'nav'/'1-column'/'2-columns' |

Handling Device Activity

‘Activity’ refers to anything that happens in the web portal which results in a call to the NAV web service. The context of the activity (the control that was used, the current state of the page) is passed to NAV and the portal expects a response containing the definition of the page that should be shown next.

You can use the following integration events in the “MES – Post Mgt.” codeunit to execute your code when ‘activity’ takes place on the portal.

OnBeforeHandleActivity

This event is called before any standard logic is executed. You can use this event to override the response to standard MES activity or define the response to your own controls. The event has the following parameters:

- PortalFrameworkControl – the temporary table containing the controls on the page

- PortalFrameworkControlData – the temporary table containing the data associated with the controls on the page

- PortalFwkApplicationDevice – a record indicating the device that the activity came from

- ActivityCode – a code denoting the type of activity that has occurred i.e. the code corresponding to the portal page that the activity took place in.

- Command – a code denoting the control on the above page that raised the activity. This code corresponds to the ControlID assigned to the control by the Page Definition codeunit. See Adding Controls.

- PortalFrameworkActivityLog – the activity log record associated with this activity

- Handled – a Boolean indicating whether this activity has been handled. A value of true will bypass any standard logic that would apply to this activity.

OnAfterDeviceActivity

This event is raised after any standard logic has been applied in response to the activity. It has the same parameter as OnBeforeDeviceActivity except for the Handled parameter, which is omitted.

- PortalFrameworkControl – the temporary table containing the controls on the page

- PortalFrameworkControlData – the temporary table containing the data associated with the controls on the page

- PortalFwkApplicationDevice – a record indicating the device that the activity came from

- ActivityCode – a code denoting the type of activity that has occurred i.e. the code corresponding to the portal page that the activity took place in.

- Command – a code denoting the control on the above page that raised the activity. This code corresponds to the ControlID assigned to the control by the Page Definition codeunit. See Adding Controls.

- PortalFrameworkActivityLog – the activity log record associated with this activity

Production Groups

MES can be customised with the concept of “Production Groups”. This provides a way of grouping prod. order lines that need to be worked on together other than by the prod. order no.

The user will be presented with a list of production groups to select from, rather than a list of prod. orders / prod. order routing lines.

Setup

MES can be configured to use production groups globally i.e. all machine centres are assigned work by production groups, by including the PROD_GROUP data type in one of the three data selection fields on the MES Setup page.

Alternatively, if some machine centres work with production groups, but not all, the “Use Production Groups” field can be set on the MES tab of the Machine Centre card.

Note: in the Process Type must be set to All Lines (rather than Single Lines) for Machine Centres that use production groups.

Implementation

The standard MES product has no definition of what a production group is, or the lines that it contains. This definition must be supplied by event subscriptions in custom code in the project.

Two key pieces of information are required by MES at various points during the workflow:

- What are the valid production groups that the user can select from?

- Which prod. order routing line(s) are included in each production group?

These questions are answered by subscribing to the following events:

COD9059236. OnBuildProdGroupSelectionBuffer

This event is used to define the valid production group(s) that the user can select. This event should be subscribed to in a custom codeunit. The parameters to the function are as follows:

- PortalFwkApplicationDevice – the record corresponding to the device that has made the call to the Portal Framework Web Service.

- This can be used to determine extra information about the call e.g. the Machine Centre or Operators that have been selected.

- PortalFrameworkControl – the selection list representing the list of production groups that will be presented to the user.

- This record should be populated with the appropriate row/column data to show to the user.

- PortalFrameworkControlData – this record represents the collection of row/column data that has been populated from the production groups.

- Handled – a Boolean that should be set to true to indicate that this event has been handled.

Example:

In this example a bespoke field has been added to the Prod. Order Line table to indicate which production group each line belongs to. This code loops through the prod. order lines to determine the distinct set of production groups related to the Machine Centre that the user has already selected.

Note: the first row of data added to PortalFrameworkControl will be used as the headings for the selection list that is presented to the user.

MESManagement.GetDeviceMachineCenter(PortalFwkApplicationDevice,MachineCenter);

PortalFrameworkControl.AddData(PortalFrameworkControlData,1,1,'Code',FALSE);

PortalFrameworkControl.AddData(PortalFrameworkControlData,1,2,'Description',FALSE);

RowNo := 1;

ProdOrderLine.SetCurrentKey("Production Group Code");

ProdOrderLine.SetFilter("Production Group Code",'>%1','');

if ProdOrderLine.FindSet() then

repeat

ProdOrderRoutingLine.SetRange(Status,ProdOrderLine.Status);

ProdOrderRoutingLine.SetRange("Prod. Order No.",ProdOrderLine."Prod. Order No.");

ProdOrderRoutingLine.SetRange("Routing Reference No.",ProdOrderLine."Routing Reference No.");

ProdOrderRoutingLine.SetRange("Routing No.",ProdOrderLine."Routing No.");

ProdOrderRoutingLine.SetRange(Type,ProdOrderRoutingLine.Type::"Machine Center");

ProdOrderRoutingLine.SetRange("No.",MachineCenter."No.");

ProdOrderRoutingLine.SetFilter("Qty. Available to Start (Base)",'>%1',0);

IF NOT ProdOrderRoutingLine.IsEmpty() THEN BEGIN

ProdOrderLine.SetRange("Production Group Code",ProdOrderLine."Production Group Code");

RowNo += 1;

PortalFrameworkControl.AddData(PortalFrameworkControlData,RowNo,1,ProdOrderLine."Production Group Code",false);

PortalFrameworkControl.AddData(PortalFrameworkControlData,RowNo,2,ProdOrderLine."Production Group Code",false);

ProdOrderLine.FindLast;

ProdOrderLine.SetRange("Production Group Code");

END;

UNTIL ProdOrderLine.NEXT = 0;

Handled := TRUE;

COD9059236.OnMarkProdOrderRtngLineForProdGroup

This event allows a custom subscriber to mark the prod. order routing lines that are related to a given production group. It will be called several times as the user navigates around the MES portal to display details appropriate to the selected production group.

The event has the following parameters:

- PortalFwkApplicationDevice - the record corresponding to the device that has made the call to the Portal Framework Web Service.

- This can be used to determine extra information about the call e.g. the Machine Centre or Operators that have been selected.

- ProdGroup – the production group which has been selected.

- ProdOrderRoutingLine – a record where the lines related to the production group should be MARKed.

- Handled – a Boolean to indicate that this event has been handled.

Example:

As above, a bespoke field has been added to the prod. order line to indicate which production group they belong to. The prod. order lines belonging to the production group are iterated through and those lines which have a prod. order routing line for the current Machine Centre, with a quantity available to start, are MARKed.

MESManagement.GetDeviceMachineCenter(PortalFwkApplicationDevice,MachineCenter);

ProdOrderLine.SetRange("Production Group Code",ProdGroup);

if ProdOrderLine.FindSet() then

repeat

ProdOrderRoutingLine.SetRange(Status,ProdOrderLine.Status);

ProdOrderRoutingLine.SetRange("Prod. Order No.",ProdOrderLine."Prod. Order No.");

ProdOrderRoutingLine.SetRange("Routing Reference No.",ProdOrderLine."Routing Reference No.");

ProdOrderRoutingLine.SetRange("Routing No.",ProdOrderLine."Routing No.");

ProdOrderRoutingLine.SetRange(Type,ProdOrderRoutingLine.Type::"Machine Center");

ProdOrderRoutingLine.SetRange("No.",MachineCenter."No.");

ProdOrderRoutingLine.SetFilter("Qty. Available to Start (Base)",'>%1',0);

if ProdOrderRoutingLine.FindSet() then

repeat

ProdOrderRoutingLine.Mark := true;

until ProdOrderRoutingLine.Next() = 0;

until ProdOrderLine.Next() = 0;

Handled := true;

Instructions

MES includes the ability to display PDF instruction sheets to users related to the operation that they are working on. The standard application allows the user to upload a PDF document against a Routing Line record.

When this routing line record is inherited by a released production order the user will see an “Instruction” button in the navigation pane in the MES portal. Clicking this button will display the PDF content in the portal window.

This functionality can be overridden by subscribing to the follow events: ### COD9059234.OnBeforeProdOrderRtngLineHasInstruction This event allows a custom subscriber to indicate if the prod. order routing line has an instruction. This is used to determine whether to display the “Instruction” button on the output screen. The event has the following parameters: - ProdOrderRtngLine - This might be a set of record if the machine center is an All Line process type - HasInstruction – set the Boolean if there is an instruction available - Handled – a Boolean to indicate that this event has been handled.

COD9059234.OnBeforeGetProdOrderRtngLineResource

This event can be used to set the resource that will be displayed on the instruction page. The event has the following parameters: - ProdOrderRtngLine – single record in question for resource - ResourceValue – resource identifier path, should be unique for each file. - i.e. the value consist of an identifier directory and a file name with the primary keys of the record which the resource is set against. - ResourceFileExtension – the file extension of resource file - Handled – a Boolean to indicate that this event has been handled.

Example:

Setting the resource from a sales order after getting the sales header of the ProdOrderRtngLine

ResourceValue := StrSubstNo('%1/%2_%3',SalesOrderInstructionDirectoryName,SalesHeader."Document Type",SalesHeader."No.");

ResourceFileExtension := 'pdf';

Handled := true;

*SalesOrderInstructionDirectoryName is a function that returns ‘/MES/SalesOrder/Instruction’

COD9059234.OnBuildPortalResourceResponse

This event can be used to return the resource file content. The resource file is cached on retrieve so the file content is only required if the file has been updated since last response. The event has the following parameters: - ResourceDirectoryName – the resource identifier directory - ResourceValue – resource file name - LastRetrieved – the downloaded DateTime - PortalFrameworkControl - record to add resource control - PortalFwkControlMetadata - record to add resource control metadata - Handled – a Boolean to indicate that this event has been handled.

Example:

case ResourceDirectoryName of

SalesOrderInstructionDirectoryName:

begin

PortalFwkApplicationDevice.SplitData(ResourceValue,ResourceKeyArray,'_');

SalesHeader.SetFilter("Document Type",ResourceKeyArray.GetValue(0));

SalesHeader.SetRange("No.",ResourceKeyArray.GetValue(1));

SalesHeader.FindFirst();

GetSalesOrderResource(SalesHeader,LastRetrieved,TempBlob,LastUpdatedDateTime);

MESSetup.Get();

PortalFrameworkControl.AddNewEntry(MESSetup."Portal Fwk. Application ID",ResourceTxt);

PortalFrameworkControl.AddMetadata(PortalFwkControlMetadata,'modifiedOn',0,FORMAT(LastUpdatedDateTime,0,''));

PortalFrameworkControl.AddMetadata(PortalFwkControlMetadata,'mimeType',0,MESPageDefinitionMgt.GetMimeType('pdf'));

if (LastRetrieved = 0DT) OR (RoundDateTime(LastUpdatedDateTime,1000,'\<') > LastRetrieved) then

PortalFrameworkControl.AddMetadataBlob(PortalFwkControlMetadata,'content',0,MESPageDefinitionMgt.BlobToBase64String(TempBlob));

Handled := true;

end;

end;

*PortalFwkApplicationDevice: Record 9059291

*MESPageDefinitionMgt: Codeunit 9059234

*GetSalesOrderResource is function which will return the resource content in TempBlob if the file has been updated since the last download. Set LastUpdatedDateTime to CurrentDateTime if not available.

CMESTMN procedure RecordDeviceStop():

Publish an event on prod. order completion so that a custom subscriber can hinge some extra logic e.g. finishing the prod. order.

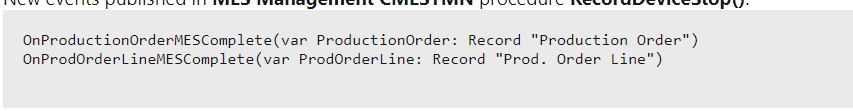

New events published in MES Management CMESTMN procedure RecordDeviceStop():

CMESTMN procedure RecordDeviceStop():