On the odd occasion an operator may need to exit their current production order for reasons other than the machine being stopped. For example, if a production order was to come to the Production Floor that had a much sooner shipping date than the order they are currently working on they may need to focus their attention on this.

MES Exit Codes are optional and do not need to be entered if not necessary.

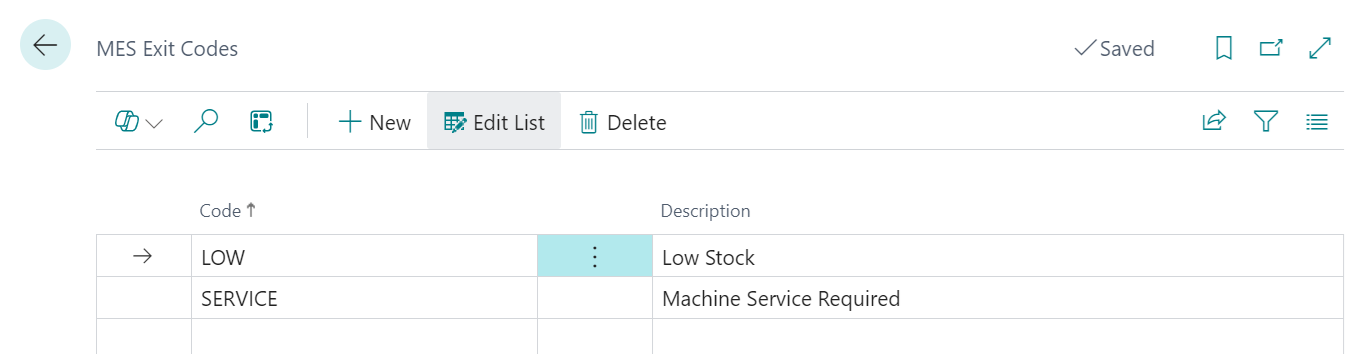

Use the search from your Role Centre to navigate to MES Exit Codes. On the MES Exit Codes page there will already been some entries on the page. These were added when the Default Configuration was run during the initial App setup.

If you plan on creating your own MES Exit Codes you must have both a Code and a Description against each record. The Code will be used to report back to the MES Device Log whilst the Description will be what the operator sees when selecting an MES Exit Code from the screen within device.

MES Exit Codes in Action

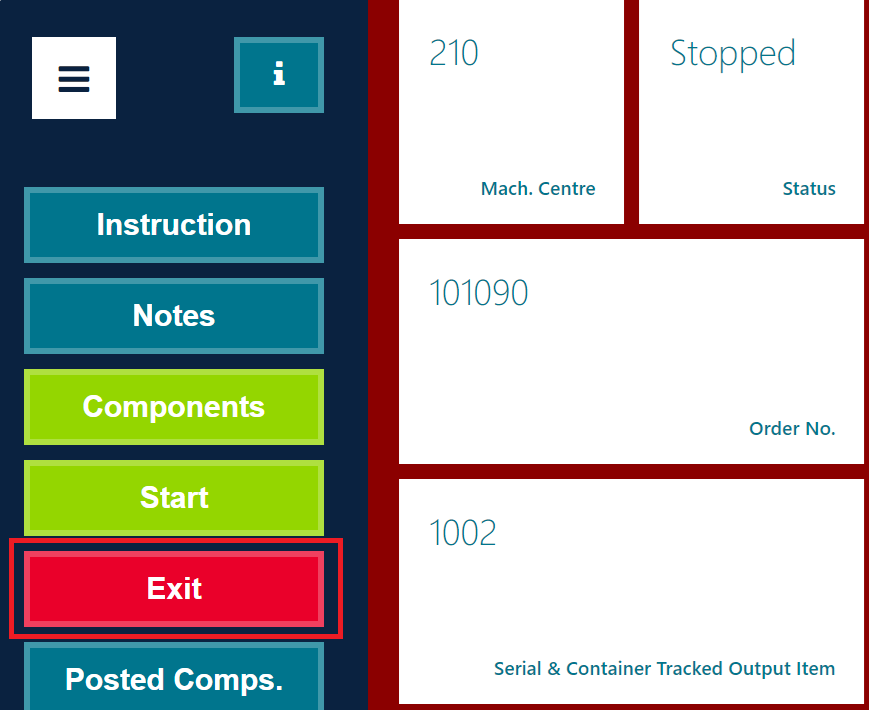

MES Exit Codes will only be visible after completing an Unplanned Stop, at which point the Output screen will show an Exit button on the navigation pane, as shown below.

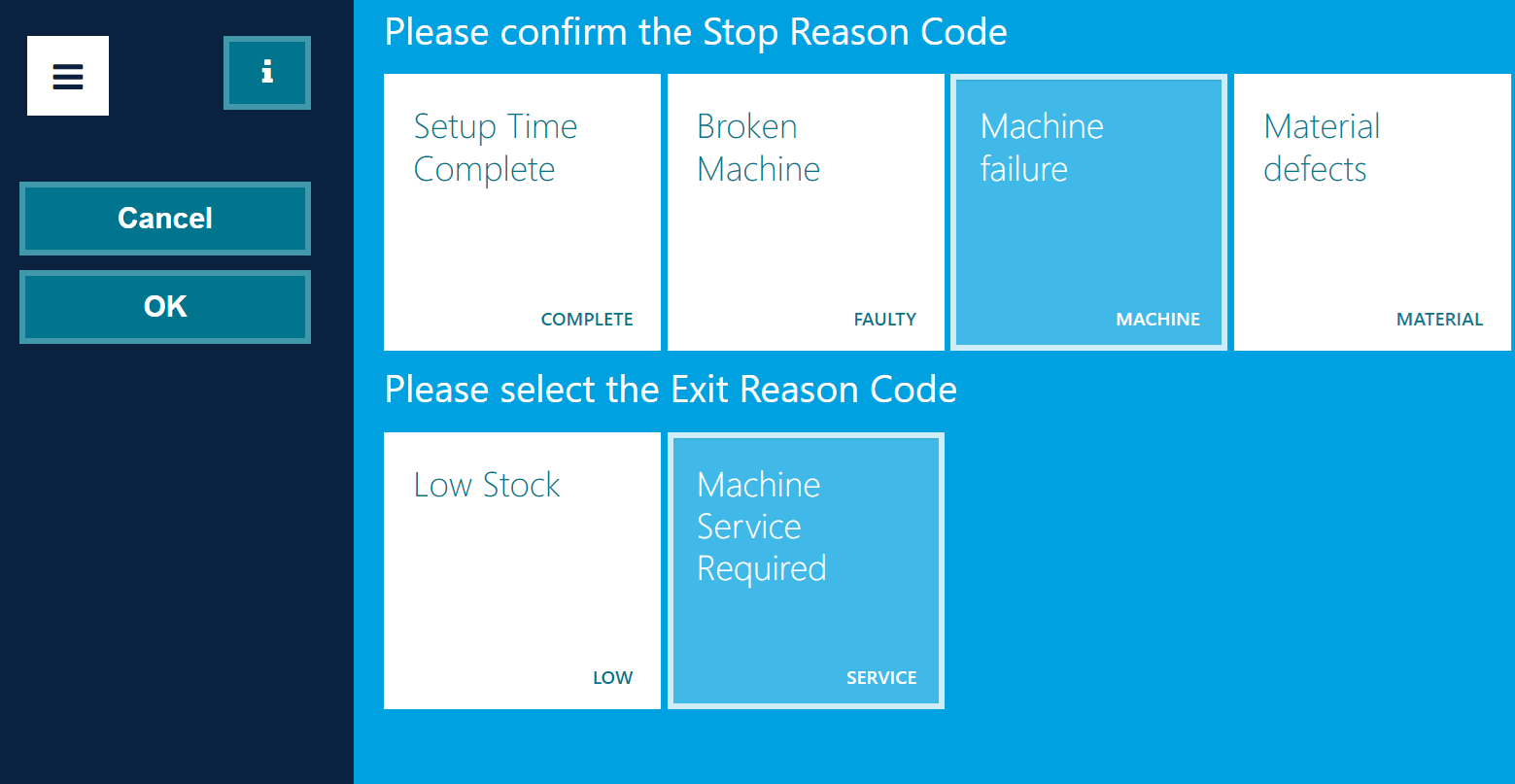

When you press the Exit button, you will be prompted to reconfirm the reason that the production order was Stopped and also to confirm the Exit Code.

Once the Stop and MES Exit Codes have been selected, the device will redirect back to the selecting a Production Order Line, from here you can still select the previously exited production line as and when it needs to be processed again.