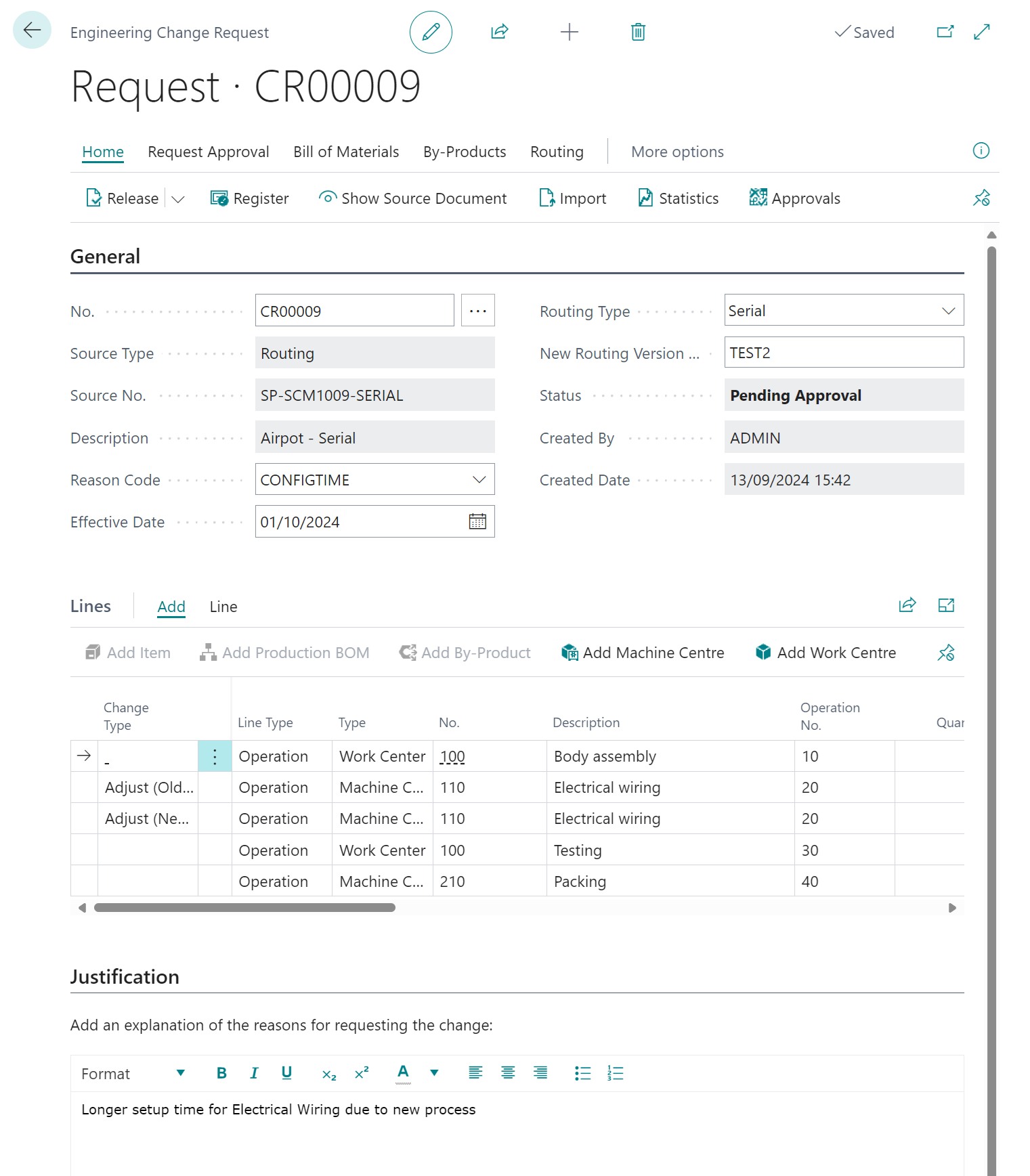

The Engineering Change Request is used to capture the requests that a user is wanting to make to manufacturing information inside of Business Central and depending on the type of change, the information stored on the "Engineering Change Request" will be different.

All information required to be included and tracked to support the request should be contained within the "Engineering Change Request" screen, enabling all users to view the same information in a central place.

An example of the "Engineering Change Request" screen is shown here for reference.

The "Engineering Change Request" is made of up of the three following sections.

| General | The General FastTab includes information about the source of the change request (BOM / Routing / By-Production / Production Order), the Reason for the change and it's Status. A key identifier of the Engineering Change Request is the Source Type which will identify the type of change the user is wishing to make |

| Lines | The Lines section will contain details of the current setup and it is this section that will be changed by the user to indicate the changes that they would like to make to the Source Type. Where adjustments are requested, the system will identify the Old and New values within the screen. |

| Justification | The user can enter qualitative information to support the reason for the change, with a viewpoint of providing clarity and context to the approver as to why the change should be implemented |

Detailed information of the attributes used for specific types of changes can be found in the following sections which detail all of the entities from which a Change Request can be generated.

-

Production BOMs

-

Production Routings

-

Production By-Products

-

Items

-

Stockkeeping Units

Regardless of the Source Type for a Production Order, the "Engineering Change Request" screen has the following options available from the menu, which are not dependant on the type of request.

| Home Menu | |

| Release | Once the information of the request has been confirmed, the Status can be set to Released. At this stage the request can either be Registered. It is not possible to use the Release option if the Approval Workflow functionality is Enabled |

| Reopen | If the request is Released and further changes are required, the Reopen option can be used to enable the request to be updated |

| Register | This option is used to register changes into the system, updating the relevant information (such as BOMs, Items and Routings) and to create the Change Control Order to track the changes that have been made. The "Engineering Change Request" will be deleted when the Register option is processed successfully |

| Show Source Document | Opens the related record, based on the Source Type and Source No. |

| Import | Will open the CAD file import process, used to import a Parts list from an external source. See here for further information. |

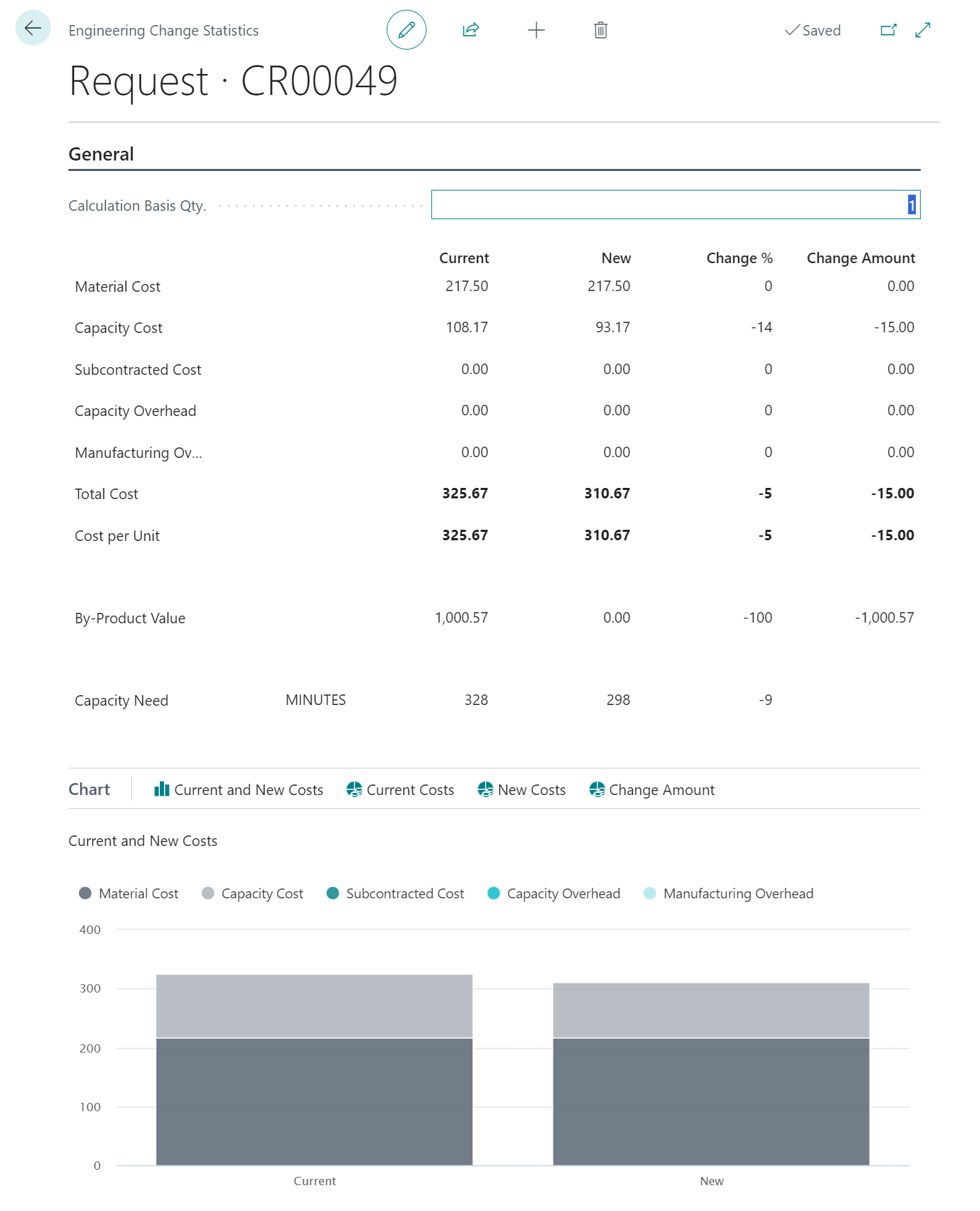

| Statistics |

Show the Statistics screen, which will detail the cost differences between the existing manufacturing setup and the impact of the changes being proposed. An example of the Statistics screen is shown here for reference.

From the Statistics you are also able to Calculation Basis Qty. field which enables you to see the effect of producing multiple units and can therefore be used to simulate costing for different batch sizes etc. |

| Approvals | Displays the list of Approval Entries that have been created in relation to the Engineering Change Request |

| Request Approval Menu | |

| Send Approval Request | When Approval Workflow is Enabled for Engineering Change Requests, this option will trigger the start of the Approval process, creating and sending Approval Emails to the relevant people |

| Cancel Approval Request | If Approval Requests have been created, but you wish to make a change to the Engineering Change Request, then you can use this option to Cancel Approvals, which will Reopen the Change Request |

Menu options that are context sensitive (e.g. relating to specific Source Type) will be documented in the relative section of the user guide.